Detection of cracks and bonding defects

in disk brake linings.

盘式制动衬片的粘接和裂纹缺陷的检测

In our Application Reports 06/97 and 07/97, we reported on ultrasonic testing of brake linings and of bonded joints in brake bodies.

在应用报告06/97 和07/97中,我们讲述了在制动体中粘接接头和制动衬片的超声检测

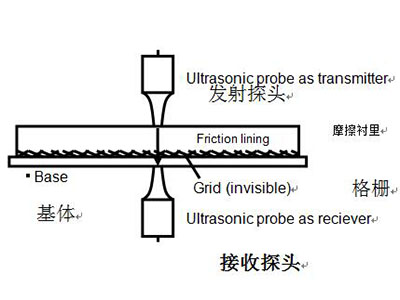

The present case deals with testing of brake bodies, consisting of a steel base plate, a welded-on grid mat as bonding agent and the sinter-fused braking substance (friction lining),

下图展示一个焊接上的网格垫作为粘接剂,钢基体和烧结熔融的制动物质组成的制动体检测。

SOLUTION:方案

The present brake lining structure with its extremely high sound absorption and scattering calls for the through-transmission technique using a test frequency of 100 kHz. We recommend the use of the probes type B 0,1 NN for this application case. This probe type enables a dry and point-to-point coupling.

由于制动衬片结构具有很高的声吸收和散射,因此需要频率为100khz的穿透法技术,推荐使用B0型1 NN 探头,这种探头类型能够实现干式和点对点耦合。

In order to ensure uniform coupling conditions, it is necessary to have a device enabling to reach a pressure force of ~100 N.

为了确保耦合的均匀,需要一个能够达到100N压力的设备

In the case of cracks and bonding defects, a low through-transmission amplitude is obtained due to the reduced acoustic transmittance. On the other hand, a high sound amplitude indicates a flaw-free area.

有裂纹和粘接缺陷的存在情况下,由于降低了声能的穿透性能,穿透技术得到的波幅会很低,另一方面,在没有缺陷的区域穿透技术得到的声波波幅会很高。

The following figure is an example of the distribution of the through-transmission amplitude (in % screen height) over the lining surface, obtained by point scanning.

下图是通过点扫,在衬面上获得穿透法波幅高度(示波屏高度百分比)分布的举例

SUITABLE EQUIPMENT:

设备

Ultrasonic flaw detectors: USM 22L USD 10NF

超声仪器

Probe: B 0,1 NN (transmitter and receiver)

探头