A method is required which can be used, after damage has occurred to diesel engines on ships or locomotives, for exami-nation, or preventative nondestructive testing of valves in the assembled condition, after the control mechanism has been removed.

This means that only the front of the valve shaft is accessible.

对去除控制机制以后的船或者机动车的柴油发动机出现损坏的情况,要求在装配的情况下对阀门进行一种检验或者是预防性的无损检测。

这就意味着只有阀门轴的前端面可以作为检测面。

SOLUTION: 方案

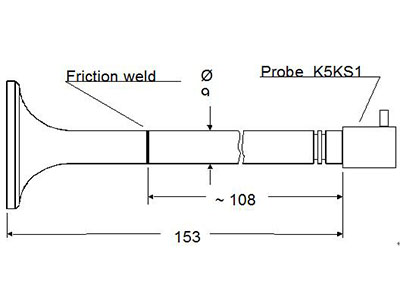

It is proposed that the special probe K5KS1 be used in the direct coupling mode on the front of the valve shaft:

特殊的探头K5KS1可用于和阀轴的前端面的直接耦合

The probe’s crystal element diameter is matched to the shaft’s diameter. The acoustically absorbent protection layer (coupling membrane) reduces coupling deviations caused by standard hard-faced probes.

探头的晶片直径和轴的端面相匹配,声学吸收保护层(耦合膜)可以降低由于探头硬接触面引起的偏差。

Indications from the weld zone are evaluated which extend above the noise level caused by coarse grain structure for-mation.

超出由于粗晶粒结构引起的噪声的焊缝区域显示进行评估

The complete weld area is covered by guiding the sound beam into the valve shafts.

调节进入阀轴的声束覆盖整个焊缝区域

Typical display indications:

典型的显示

It is recommended that the test method be used due to its easy application and its clear indications in engine production and for input checks.

推荐的检测应用简单并且能够形成清晰的显示

SUITABLE EQUIPMENT: 设备

Ultrasonic Flaw Detector:

超声设备 USD 15X USM 22 USM 25

Probe: K5KS1

探头