BRANCH:涉及领域 Foundries, Machine construction

铸造,机械制造

TASK:任务 Wall thickness measurement on cast

camshafts

铸件凸轮轴的厚度测量

A nondestructive method is required to detect the typical defect in casting, viz. “core mismatch”.

无损检测用于发现铸件中典型的缺陷,即“芯模错位”

In consequence of this mismatch, reduced wall thicknesses occur leading to a failure of the camshaft in operation because of its lean geometry and due to the extreme dynamic load.

由于芯模错位的存在,导致壁厚减薄的区域在凸轮轴运行过程中因芯模几何形状的倾斜和极端的动载荷将导致凸轮失效

SOLUTION: 方案

The recommended solution is to measure the wall thickness on the bearing points.

推荐的方法是测量轴点上的壁厚

The simple, annular geometry of these points allows to carry out the test on the shaft as cast. Further processing actions on any defective parts are thus excluded.

这些点简单,环形的几何形状允许在铸造的过程中对轴进行检测,从而使进一步的加工处理部件没有缺陷

This method makes it possible to recognize the core mismatch by a reduced wall thickness and excessive wall thickness opposite (180°).

这种方法通过测量壁厚的减薄和对面壁厚的增加使识别芯模错位成为可能

The waterflow (squirter/bubbler) technique is applied according to the arrangement shown in the sketch.

根据示意图上显示的布局水柱法可以被应用

This ensures a constant coupling in the area of the bearings around the entire circumference during camshaft rotation.

这样确保了在凸轮轴旋转的过程中能够对整个轴的圆周面有一个稳定的耦合

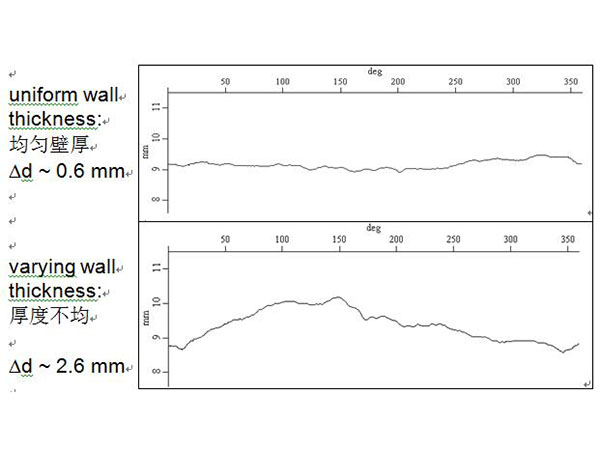

Typical linear scans 典型的线性扫查

(wall thickness [mm] around the circumference [360o])

周向壁厚扫查

Circumferentially

developed view:

周向视图

SUITABLE EQUIPMENT:

设备

Ultrasonic flaw detectors: 设备 USD 15X or USPC 2100

Probe:探头 H 2 KF

Accessories:附件 Multiplexer MUX D

Software :软件 UltraMAP