BRANCH:涉及领域 Foundries, hardening shops, combustion engine construction

铸造,硬化加工,燃机建造

TASK:任务 Hardness testing on the running surfaces of camshafts

在凸轮轴的运行表面上进行硬度测试

In order to attain adequate service lives, that means high capacity of resistance to wear, camshaft running faces are hardened, for example in the laser beam remelting process.

为了获得足够的服务期限,意味着凸轮轴的表面要有高的耐磨性能,可以通过表面硬化来实现,比如激光重熔工艺

It must be ensured in this process that the martensitic micro-structure is developed uniformly over the camshaft contour by exact thermal processes and time sequences.

通过加热工艺和时间顺序确保凸轮轴表面能形成均匀的马氏体结构

This process is checked by means of hardness testing. This calls for a method that keeps the necessary time expenditure within certain limits even with statistically required multiple measurements.

通过硬度实验对这项工艺进行核查, 这项工艺在一定的期限内需要花费必要的时间甚至需要进行多种硬度测试

SOLUTION: 方案

We recommend the hardness test according to the UCI method.

推荐应用UCI方法进行硬度测试

Using the test load of 0.3 kgf (3 N) and 1 kgf (10 N) respectively, an approximative nondestructive surface hardness determination is achieved (experience shows that the indentation depths of Vickers diamonds are at around 4 to 7 μm).

通过分别施加0.3 kgf (3 N) 和1 kgf (10 N)载荷来获得近似的且表面没有损坏的硬度值(经验得出维氏金刚石的压痕深度大约在4-7 μm之间)

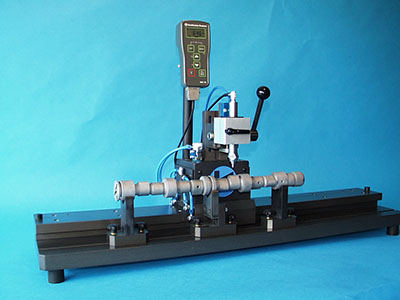

The measuring process is considerably simplified by the special test support MIC 225 for hardness testing on camshafts.

通过应用MIC225进行凸轮轴硬度实验大大简化了检测过程。

This is achieved by mounting the camshaft in vee-blocks and an air bearing slide carriage with probe support guiding the measuring device parallel to the shaft axis. The torsion of the shaft during the measuring process is prevented by a magnetic locking.

通过将凸轮轴安装在V形块中和带有探头支架的空气轴承滑座上实现的,该装置平行于凸轮轴线,在测量过程中轴的扭矩是通过磁锁进行给固定的。

This ensures an exact positioning of the probe on the camshaft base circle or camshaft tip.

确保了探头在凸轮轴的弧面和尖端接触的精确的定位。

SUITABLE EQUIPMENT:

设备

Hardness tester: MIC 10, MIC 10 DL

硬度计

Probes: MIC 2003-A (motor probe)

MIC 201-A (hand-held probe)

探头

Accessories: MIC 225 (camshaft test support)

附件